Overview

This topic introduces the purpose and procedure of cleaning optical fiber connectors, as well as polluters to optical fiber connectors.

Cleaning fiber connectors is to remove dust or other dirt to avoid performance degradation of optical transmission systems.

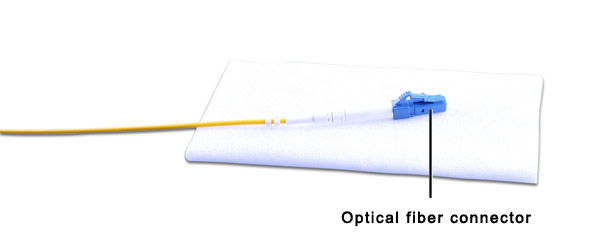

Figure 1 shows an optical fiber connector.

Optical fiber connectors should be free of:

Dust

Grease (usually brought by hands)

Condensate residue

Powder (evaporated residue of water or solvent)

Dust is the most common dirt in optical fiber connectors. The dust particles that can be seen only by a microscope can affect the quality of optical signals, deteriorate the system performance, and cause instability in network operation.

A 1-micrometer dust particle on the single-mode fiber connector can block 1% light and cause 0.05 dB attenuation. A 9-micrometer dust particle that cannot be seen by human eyes can block an entire fiber core. Therefore, small dirt even that cannot be seen by human eyes should be removed.

Before you connect any optical component, make sure that you have checked and cleaned the component.

Procedure

Table 1 describes the procedure of inspecting and cleaning the optical fiber connectors and adapters.

Step |

Details |

|---|---|

Clean optical fiber connectors using the cassette cleaner |

See "Cleaning Optical Fiber Connectors Using the Cassette Cleaner". |

Clean optical fiber connectors using lens tissue |

See "Cleaning Optical Fiber Connectors Using Lens Tissue". |

Clean optical fiber adapters using dustfree absorbent swabs |

See "Cleaning Optical Fiber Adapters Using Dustfree Absorbent Swabs". |