Inspecting Optical Fiber Connectors

This topic describes how to inspect the end face of optical fibers using a fiber microscope.

Tools, Equipment, and Materials

The following provides the required tools, equipment and materials for inspecting optical fiber connectors:

Optical power meter

400X fiber microscope (A video fiber microscope is recommended.)

Precautions

Laser energy is invisible and may cause eye injuries. Never look directly into fiber connectors or ports.

Use a fiber microscope equipped with a safety device or a desktop video fiber microscope when inspecting the optical fiber connectors.

Electrostatic discharge is hazardous to the electronic equipment. Wear an ESD wrist strap and ensure that the strap is grounded properly before touching the equipment and boards, to protect the static-sensitive components against electrostatic discharge of the human body. Otherwise, the equipment may be damaged or the service may be interrupted.

Procedure

Shut down the laser and disconnect the fiber end before inspecting the fiber connector.

Test the optical power using a power meter to ensure that the laser is shut down.

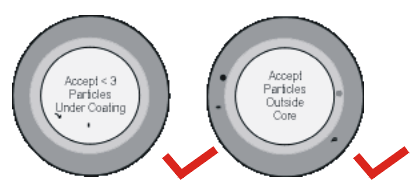

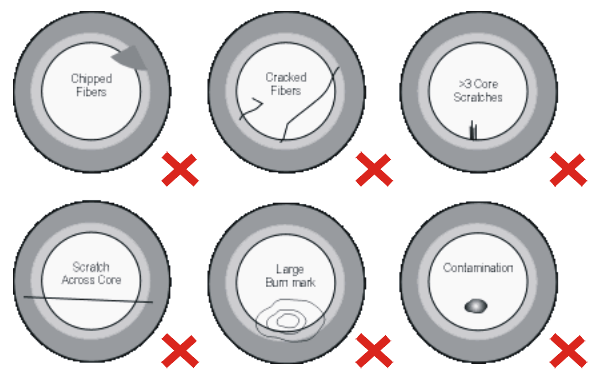

Use a fiber microscope to check whether the fiber connector is contaminated or damaged. See the examples below.

- Clean fiber and face

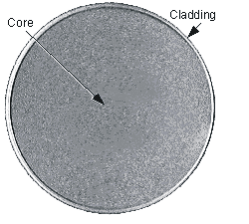

Figure 1 shows an image of a clean fiber end face under the fiber microscope.

- Damaged fiber end face

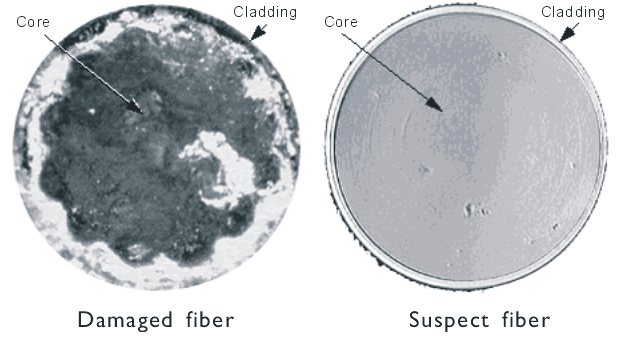

Figure 2 shows images of the damaged fiber end face. The image on the left shows a severely damaged fiber. Severely damaged fibers can cause damage to the equipment and should not be used. The image on the right shows a defective fiber. If the output power is within a certain range, the defective fiber might not cause any damage to the equipment. If the output power is unstable or out of the range, however, the defective fiber can cause damage to the equipment.

For details on acceptable and unacceptable fibers, see Figure 3, Figure 4 and Figure 5.

- Clean fiber and face

If any dirt is detected, clean the optical fiber connector. For details, see "Cleaning Optical Fiber Connectors Using the Cassette Cleaner" and "Cleaning Optical Fiber Connectors Using Lens Tissue".

If any damage is detected, replace the fiber.