Cleaning Optical Fiber Connectors Using Lens Tissue

This topic describes how to clean the fiber connectors using lens tissue.

Prerequisites

Before cleaning, inspect the fiber end face with a fiber microscope or a magnifier to confirm the degree of fiber contamination. Clean the fiber only when it is severely contaminated. This is because the cleaning operation itself may introduce dust, dirt, or cause damage to the fiber.

Tools, Equipment, and Materials

Optical power meter

400X fiber microscope (A video fiber microscope is recommended.)

Cleaning solvent (Isoamylol is preferred, propyl alcohol is the next, and alcohol or formalin is forbidden.)

Non-woven lens tissue, fiber cleaning tissue, and dustfree cloth (Non-woven lens tissue is recommended.)

Special compressed air or cleaning roll

Precautions

Laser energy is invisible and may cause eye injuries. Never look directly into fiber connectors or ports.

Electrostatic discharge is hazardous to the electronic equipment. Wear an ESD wrist strap and ensure that the strap is grounded properly before touching the equipment and boards, to protect the static-sensitive components against electrostatic discharge of the human body. Otherwise, the equipment may be damaged or the service may be interrupted.

Procedure

Shut down the laser and disconnect the fiber end before inspecting the fiber connector.

Test the optical power using a power meter to ensure that the laser is shut down.

Put a little cleaning solvent on the lens tissue.

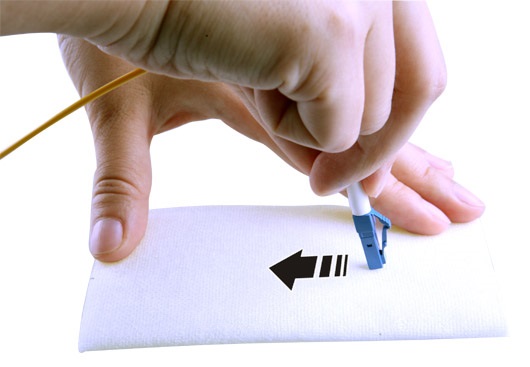

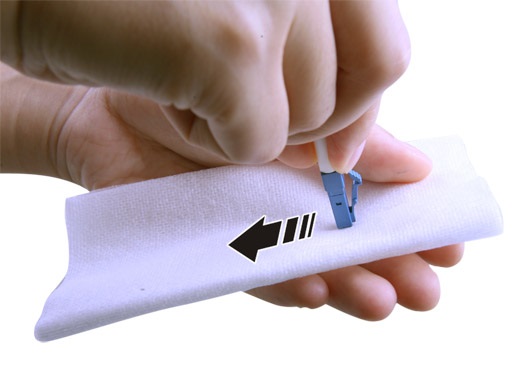

Clean the fiber end face on the lens tissue. See Figure 1 and Figure 2.

Drag the fiber end face on the same area in the lens tissue only once. Otherwise, the connector can be contaminated or damaged.

Repeat 4 several times on the areas of the lens tissue that have not been used.

Use the compressed air to blow off dust on the fiber end face.

When using the compressed air, keep the nozzle as close as possible to the fiber end face without touching it.

Before using the compressed air, first spray it into the air to expel deposits in the compressed air.

If the compressed air is not available, use a cleaning roll instead.

Use a fiber microscope to inspect the fiber to check whether there is any dirt. For details, see the examples shown in "Inspecting Optical Fiber Connectors". If the fiber end face is still dirty, repeat 1 to 6.

Do not touch the fiber connector after cleaning it. Connect it to the optical port immediately. If it is not used for the time being, put a protective cap on it.

Do not use the same cleaning area to clean the fiber connector for more than one time.

Turn on the laser after connecting the fiber to the board.